Reason

From the Quicksilver Metaweb.

This is the Snow Crash page for Reason

Stephensonia

Gatling Gun

Big gun that invokes all the big gun movie cliches ... such as:

Dick Durkin: We need to get bigger guns. BIG FUCKING GUNS!

This is something that spans much of Neal Stephenson's works ... but brought to birth in Snow Crash.

... "It's okay, I'm sure they'll listen to Reason," Fisheye says. ...

Fisheye is up on his knees now and has torn away the canopy and space blanket that have covered him until this point. In one hand he is holding a long device a couple inches in diameter, which is the source of the whirring noise. It is a circular bundle of parallel tubes about pencil-sized and a couple fee long, like a miniaturized Gatling gun ...R E A S O N*

version 1.0B7

Gatling-type 3-mm hypervelocity railgun system

Ng Security Industries, Inc.

PRERELEASE VERSION - NOT FOR FIELD USE

DO NOT TEST IN A POPULATED AREA

- ULTIMA RATIO REGUM*

Authored entries

- action at a distance (Albert Einstein)

- action at a distance (Rene Descartes)

- action at a distance (John Doe)

- Action at a distance (Jane Smith)

- Stephenson:Neal:Quicksilver:518:Ultima Ratio Regum (Jeremy Bornstein)

- Stephenson:Neal:Quicksilver:518:Ultima Ratio Regum (Mike Lorrey)

- Stephenson:Neal:Quicksilver:747:A Swiss mathematician named Fatio (Neal Stephenson)

Description

Richard Jordan Gatling

Reason, version 1.0B7, is the name of a prototype miniature Gatling gun produced by Ng Security Industries, Inc. which Ng has lent to the Mafia for this operation. It is a 3-mm hypervelocity railgun.

It is stamped with the motto "Ultima Ratio Regum", which is latin for "Last Argument of Kings", a motto which France's King Louis XIV had stamped on all his cannon.

Fisheye's developing attachment to it's power is his undoing as he is killed by a primitive glass tipped harpoon flung by Raven. This deadly infatuation is commented on by Ng as something experienced by US troops in Vietnam.

The specs Stephenson used for this gun appear to be an evolution of the FN-GAR gaussgun used in the game TORG, with Reason being an improvement in having the radiothermovoltaic nuclear power source rather than a power pack requiring recharge after 200 rounds.

A superconducting version of the coilgun is called the quench gun. Resistors attached to superconductive coils waste energy in the coil, which is turned into heat. After a time this heats the superconductor up to the point where it is no longer a superconductor, thereby changes its state to normal (non-superconducting). When this happens the resistance of the coil as a whole suddenly increases, dumping all of the power as heat at a very rapid rate. By carefully controlling the heating rates, the magnets can be "turned off" in sequence at the proper rates to make a coilgun, one that generates very powerful magnetic fields with high efficiency, and tends to have lower hysteresis due to the rapid "burn out" of the energy in the coil.

One advantage of the coilgun over the railgun is that it can be made arbitrarily long. This has a number of side effects, but the main one is that the acceleration can be much slower over a longer length, meaning that the power needed in any one section of a coilgun is much lower. However this advantage is offset by the cost and complexity of the switching system needed to supply a longer gun.

Origins of the Gatling

In 1862 Richard Jordan Gatling, took out a patent for a mechanical gun that he developed. The Gatling Gun consisted of six barrels mounted in a revolving frame. A later version with ten barrels, fired 320 rounds a minute. The United States Army purchased these guns in 1865 and over the next few years most major armies in Europe purchased the gun.

In 1870 Gatling opened a new factory in Hartford, Connecticut to produce his gun. He continued to improve the Gatling Gun and by 1882 it could fire up to 1,200 rounds per minute. However, sales of the gun declined after Hiram Maxim began producing his automatic Maxim Machine Gun.

Richard Jordan Gatling

Richard Jordan Gatling was born in Money's Neck, North Carolina. He studied medicine and dentistry but never practised. In 1862 Gatling took out a patent for a mechanical gun that he developed. The Gatling Gun consisted of six barrels mounted in a revolving frame. A later version with ten barrels, fired 320 rounds a minute. The United States Army purchased these guns in 1865 and over the next few years most major armies in Europe purchased the gun.

As well as guns, Gatling manufactured machines for sowing and breaking hemp, a steam power and a marine steam ram. Richard Jordan Gatling died in 1903.

His Gun (from Gatling Gun)

1865 Patent drawing for

Gatling's Battery Gun'

The Gatling gun was the first successful Machine Gun. Unlike previous devices it was the first to combine reliability, high firing rate and ease of loading into a single device. It was designed by the American inventor Richard J. Gatling in 1861 and patented on May 9, 1865.

The design took advantage of the new brass bullet cartridge that had replaced the paper cartridge. The gun was a hand-driven rotary device, powered using a crank. A cylinder of ten barrels would be loaded and fired for each revolution. The loading was a simple gravity feed from a magazine mounted on top of the weapon. The maximum rate of fire was a possible 1,200 rounds per minute, although 400 was more reasonable. The gun was produced in calibers ranging from one inch down to 0.45 inch. It was operated by a crew of four.

The barrels, a carrier, and a lock cylinder were separate and all mounted on a solid plate revolving around a central shaft, mounted on an oblong fixed frame. The carrier was grooved and the lock cylinder was drilled with holes corresponding to the barrels. Each barrel had a single lock, working in the lock cylinder on a line with the barrel. The lock cylinder was encased and joined to the frame. The casing was partitioned, through this opening the barrel shaft was journaled. In front of the casing was a cam with spiral surfaces. The cam imparted a reciprocating motion to the locks when the gun rotated. Also in the casing was a cocking ring with projections to cock and fire the gun.

Turning the crank rotated the shaft. Cartridges, held in a hopper, dropped individually into the grooves of the carrier. The lock was simultaneously forced by the cam to move forward and load the cartridge and when the cam was at its highest point the cocking ring freed the lock and fired the cartridge. After the cartridge was fired the continuing action of the cam drew back the lock bringing with it the spent cartridge which was then dropped to the ground.

The grouped barrel concept was not new, it had been tried since the 18th century, but poor engineering and the lack of a metal cartridge made the attempts unsuccessful. The innovative features of the Gatling gun were its independent firing mechanism for each barrel and the simultaneous action of the locks, barrels, carrier and breech.

The smallest calibre gun also had a Broadwell drum feed in place of the curved magazine of the other guns. The cartridge holder was divided into sixteen sections each holding 25 cartridges. As each section was emptied the drum rotated bringing a new section into use until all 400 rounds had been fired.

The concept was made obsolete with the development of the gas or recoil blowback concept, which is the basis of modern machine guns, such as the Maxim, the Vickers, the Browning Automatic Rifle and the Browning Potato Digger, M-1 Garand, M-14, M-60, and modern infantry rifles such as the M-16 and the AK-47.

However, Gatling-style guns with rotating barrels were to return as very high rate-of-fire weapons in military aircraft and ship-based anti-missile defence systems. They now commonly use electric motors, rather than cranks, for rotation. One example is the M61 Vulcan 20mm cannon, the most commonly used member of a family of weapons designed by General Electric. The Vulcan is a six-barrelled electric Gatling capable of firing more than 6,000 rounds per minute, a rate unachievable with a conventional machine gun. A variety of similar weapons are available in calibers ranging from 5.56mm to 30mm, the rate of fire being somewhat proportional to the size and mass of the ammunition (which also determines the size and mass of the barrels).

30mm Gatling Gun System

The GAU-8 Gatling gun of an

A-10 Thunderbolt II at Osan Air

Base, Korea

The GAU-8/A produced by General Dynamics Armament and Technical Products (GDATP) is a 30mm Gatling gun system installed on the U.S. Air Force's A-10 Thunderbolt II aircraft and the Goalkeeper Close-In Weapon System. The GAU-8/A provides a reliable, high-rate-of-fire, combat-proven weapon system for close air support and shipboard defense missions.

Specifications:

Gun Type: Seven-Barrel, 30mm, Externally Powered Gatling Gun

Weight: 620 Pounds (281 kg)

Rate of Fire: Up to 4,200 Shots Per Minute

Dispersion: 5 Milliradians Diameter, 80 Percent Circle

Muzzle Velocity: 3,400 Feet (1,036m) Per Second

Average Recoil Force: 10,000 Pounds (44.5 kN)

Drive System: Hydraulic, Electric, Pneumatic

Feed System: Linked or Linkless

Wikipedia: Railgun

This article is about an electromagnetic projectile launcher. you may be looking for railway gun.

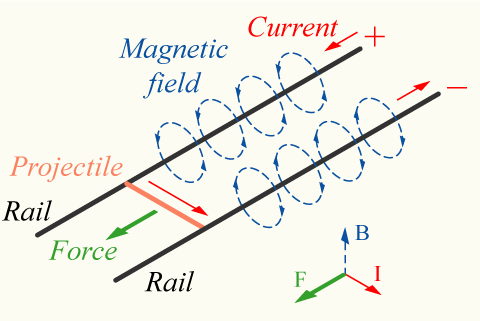

A railgun (not to be confused with a Gauss gun, which is another name for a coilgun), is a form of gun that converts electrical energy into projectile kinetic energy, rather than the more conventional chemical energy from an explosive propellant.

Homebrew Prototype RailgunRailguns utilize a magnetic force termed "Lorentz force" to propel an electrically conductive projectile that is initially part of the current path. The current flowing through the rails sets up a magnetic field between them and through the projectile perpendicularly to the current in the rail. This results in a mutual repulsion of the rails and the acceleration of the projectile along them.

Theory and construction

Although conceptually simple, the operation of a railgun involves several factors that have to this day made a practical design (one that can be fielded and replace conventional weapons) impossible.

A wire carrying an electrical current, when in a magnetic field, experiences a force perpendicular to the direction of the current and the direction of the magnetic field. This is the principle behind the operation of an electric motor, where fixed magnets create a magnetic field, and a coil of wire is carried upon a shaft that is free to rotate. When electricity is applied to the coil of wire a current flows, causing it to experience a force due to the magnetic field; the wires of the coil are arranged such that all the forces on the wires act to make the shaft rotate, and so the motor runs.

A railgun is even simpler than a motor. It consists of two parallel metal rails (hence the name) connected to an electrical power supply. When a conductive projectile is inserted between the rails (from the end connected to the power supply), it completes the circuit. Electrical current runs from the positive terminal of the power supply up the positive rail, across the projectile, and down the negative rail back to the power supply again.

Schematic diagram of a railgun by WikiPedia's DrBob

This flow of current makes the railgun act like an electromagnet, creating a powerful magnetic field in the region of the rails up to the position of the projectile. In accordance with the right-hand rule, the created magnetic field circulates around each conductor. Since the current flows in opposite direction along each rail, the net magnetic field between the rails (B) is directed vertically. In combination with the current (I) flowing across the projectile, this produces a Lorentz force which accelerates the projectile along the rails. There are also forces acting on the rails attempting to push them apart, but since the rails are firmly mounted they cannot move. The projectile is able to slide up the rails away from the end with the power supply.

If you happen to do this with a very large power supply, providing a million amperes or so of current, then the force on the projectile will be tremendous, and by the time it leaves the ends of the rails it can be travelling at many kilometres per second.

Although these speeds are theoretically possible, the heat generated from the propelling the object is enough to actually vaporise the rails. This would result in very fast erosion of the rails themselves. So either they will have to be replaced often or a new material has to be made for them.

The complexity in railgun design comes from:

- The need for strong conductive materials with which to build the rails and projectiles; the rails need to survive the violence of an accelerating projectile, and heating due to the large currents involved and friction. The force exerted on the rails consists of a recoil force - equal and opposite to the force propelling the projectile, but along the length of the rails (which is their strongest axis) - and a sideways force caused by the rails being pushed by the magnetic field, just as the projectile is. The rails need to survive this without bending, and must be very securely mounted.

- Power supply design. The power supply must be able to deliver large currents, with both capacitors and compulsators being common.

- Electromechanical design. The rails need to withstand enormous repulsive forces during firing, and these forces will tend to push them apart and away from the projectile. As rail/projectile clearances increase arcing develops which causes rapid vaporization and extensive damage to the rail surfaces and the insulator surfaces. This limits most research railguns to one shot per service interval.

There are fundamental limits to the exit velocity due to the inductance of the system and in particular the rails. These limits are larger than currently attainable but do reduce the usefulness of the concept for space travel and military uses.

Railguns as weapons

Railguns are being pursued as weapons with projectiles that do not contain explosives, but are given extremely high velocities: 3500m/s or more (for comparison, the M16 rifle has a muzzle speed of 975m/s), which would make their kinetic energy equal or superior to that of an explosive-filled shell of greater mass. This would allow more ammunition to be carried and eliminate the hazards of carrying explosives in a tank or battleship. Also, by firing at higher velocities railguns have greater range, less bullet drop and less wind drift. It is postulated that the next generation of reactive armor will be impenetrable by conventional ammunition and shaped charges; the higher velocity KE-penetrator projectiles of railguns would be able to easily defeat such armour.

Although full scale guns have been built and fired, including a very successful 90 mm bore, 9MJ kinetic energy gun developed by DARPA, they all suffer from extreme rail damage and need to be serviced after every shot. Rail and insulator ablation issues still need to be addressed before railguns can start to replace conventional weapons.

The United States military is funding railgun experiments. At the University of Texas' Center for Electromechanics, military railguns capable of delivering tungsten armor piercing bullets with [kinetic energy|kinetic energies]] of nine million joules have been developed. Nine million joules is enough energy to deliver 1 kg of projectile at 3 km/s - which will tear a tank to pieces in a single shot.

Due to the very high muzzle velocity that can be attained with railguns, there is interest in using them to shoot down high-speed missiles.

Naval forces are also interested in railgun research. Current ship guns store their explosive shells in a large magazine underneath the gun. If a shell from a hostile ship should happen to penetrate into the armoury and explode, it is quite likely to cause all of the shells in the magazine to detonate, usually destroying the ship. However if the ship is instead equipped with railguns, the magazine would need only to store the non-explosive tungsten bullets. Additionally, the compact railgun projectiles would require less space to store than the shells used for current guns. Electricity for the railgun could be supplied from an on-board compulsator, which in turn could be powered by the ship's engines.

Peaceful uses of railguns

There is interest in using railguns as mass drivers for space exploration and mining. They would be useful for launching bulk ores into space, particularly from low-gravity bodies such as moons and asteroids; electrically powered from solar panels, they would not require any consumables such as rocket fuels.

Rail guns have been proposed for use in delivering projectiles to space, especially from bodies without atmospheres (such as the Moon). Its main competitors are coil guns and ram accelerators.

Also, railguns may be used to initiate fusion reactions, by firing pellets of fusible material at each other. The impact would create immense temperatures and pressures, allowing nuclear fusion to occur. However current railguns are not yet sufficient to achieve the energies required.

Railguns in science fiction

Eraser's Mobile Railgun

Railguns have started to appear in sci-fi and become a mainstream idea. However, they have not always been portrayed accurately.

In Robert Heinlein's classic novel The Moon is a Harsh Mistress, rebelling Lunar colonists convert a kilometers-long mass driver system that delivers raw materials to Earth into a basic railgun that lobs metal-clad rocks.

In the film Eraser, the lead character gets hold of a device like a chunky rifle that is said to be a man-portable railgun. It is shown firing bullets through great numbers of walls and so on, and it makes a blue trail in the air. In many computer games, such as Red Faction, Red Faction II, and the Quake series, railguns are common weapons.

Two devices identified as railguns appear in the Metal Gear series. One is mounted on Metal Gear REX, and its description is in fact more similar to that of a Coilgun. The other is an experimental and highly unstable man-portable weapon in Metal Gear Solid 2, supposedly a miniature of MG-REX's railgun (which would make it a coilgun). However, somewhat confusingly, electrical arcs during its use suggest it might actually be a railgun.

The book Snow Crash features an experimental railgun weapon codenamed Reason (p.338).

The novel series Buck Rogers uses Mass driver railguns on Luna.

The Tau in Warhammer 40,000 use railguns extensively.

In the video game, Halo 2, there are orbital MAC (Magnetically Accelerated Cannon) guns that fire metal ignots into alien starships to penetrate their energy shields and punch holes in their superstructure.

In Starsiege Tribes there are railguns, which are just modified versions of laser rifles, with different projectile than its design (It uses explosive bullets, not laser projectiles) and quite often is designed and programmed with another weapon attached to it.

In the anime Gasaraki, railguns were mounted on robots. The projectile left a red streak and melted through everything it penetrates. In the anime Gundam Seed, railguns (in some cases referred to as linear guns or gun launchers, though in the context of the series there seems to be little if any difference between them) of various sizes are commonly mounted on both space warships and smaller one-man machines called mobile suits and mobile armors. The projectile is typically animated as a yellow streak.

Quake III Railgun

However, man-portable railguns will not be revolutionary weapons; if power supply technology ever lets us make a railgun supply small enough to be carried then rail-handguns will probably only be able to fire projectiles at speeds not much higher than currently achieved with chemical propellants. The simple reason is that the destructive power of a handgun or long gun is limited as much by recoil as anything else; we can quite happily build a handgun that fires 20 mm cannon shells, but you couldn't fire it without having your hand broken.

One possible route to explore is a portable railgun that fires very small bullets. The recoil of a weapon is caused by the momentum of the escaping projectile yet the damage done by the projectile is more related to its kinetic energy. The momentum of the projectile is its mass times its velocity, but the kinetic energy is one half of the mass times the velocity squared. So a very small, very fast, projectile could deliver a moderate recoil, but be carrying enough kinetic energy to vaporise upon impact and burn a large hole in armour and flesh alike. However, such a weapon would not fire through walls very well; the projectile would vaporise upon contact with the first wall. See needlegun.

A kinetic energy penetrator, long-rod penetrator, or APFSDS (Armour Piercing Fin Stabilized Discarding Sabot) is a type of ammunition which, like a bullet, does not contain explosives, but uses kinetic energy to penetrate the target. The term is used for more powerful projectiles than ordinary bullets: they are capable of penetrating armor due to: 1. being fired with a very high muzzle velocity 2. concentrating the force on a small area without having too small a mass, and therefore having the form of a long sleek rod

To produce very high speeds the ammunition is normally composed of a narrow penetrator surrounded by a sabot which expands the diameter to the full barrel width of the firing gun. This allows the pressure of the propellant gases to act on the full-size base and produce rapid acceleration of the round, which is lighter than a full metal round of the same diameter would be. Once the round leaves the barrel the sabot falls off, leaving the penetrator travelling at high speed and with a smaller cross-sectional area, which reduces aerodynamic drag during the flight to the target. This technique was first used in anti-tank guns during World War 2; Germany developed sabots under the name "Treibspiegel".

KE-penetrators for tanks are commonly just 2â3 centimeters in diameter, and 50â60 centimeters long; as more modern penetrators are developed, their length tends to increase and the diameter to decrease. To maximize the amount of kinetic energy released on the target, the penetrator must be made of a heavy material, such as tungsten or DU (depleted uranium). The hardness of the penetrator is of lesser importance. In fact uranium is not particularly hard. An advantage of uranium is that it is pyrophoric: the molten fragments of the penetrator ignite on contact with air. Uranium rod is also self-sharpening on impact.

Few countries use DU ammunition because of its cost and environmental effects. Battle sites where DU rounds have been used typically have residual uranium dust in and around battle-damaged vehicles. This dust is mildly radioactive and toxic, thus the lingering effects of it can create public relations problems.

Because a long, thin rod is aerodynamically unstable and tends to tumble in flight, two different approaches have been used to stabilise them. The oldest is rifling, which spins the round. An alternative approach is to add fins like those of an arrow to the base and fire the round from a smooth-bore gun. This is the approach commonly used in recent Russian, German and US guns. Sometimes a rifled barrel has been combined with fin stabilisation, using some system to prevent the round from spinning in the barrel. The rifled barrel approach improves the accuracy of the other types of ammunition which must be fired. An example of this is the L30 120 mm rifled tank gun used on the United Kingdom Challenger 2 MBT.

It is generally accepted that KE-penetrators are the most effective ammunition in penetrating armour today. The other main type of tank ammunition is High explosive anti-tank (more common in missiles). The British prefer HESH (High Explosive Squash Head).

The counterpart of a KE-penetrator in rifle ammunition is the flechette. A rifle firing flechettes, the Special Purpose Individual Weapon, was under development for the US Army, but the project was abandoned.

Wikipedia: Special Purpose Individual Weapon

The Special Purpose Individual Weapon (SPIW) was a long-running US Army program to develop a workable flechette based "rifle". Developed primarily by Irwin Barr, one of the founders of AAI (Aircraft Armaments Inc.), the program developed weapons over a 15 year period but was never adopted. The concept was revived in the 1980s as a part of the Future Rifle Program and again in the 90s under the Advanced Combat Rifle program, but neither program resulted in a system useful enough to warrant replacing the current M16.

The idea of a flechette-based individual weapon started in earnest during the Army's Project SALVO. SALVO had earlier concluded that a small weapon with a high rate of fire would be considerably deadlier than the large "full power" weapons being developed in the 1950s, and followed several lines of investigation to find the best solution. SALVO had a small number of "duplex load" weapons developed, where two bullets were stacked, while Springfield and Winchester both entered multi-barrel weapons.

Even before the SALVO tests, Barr had been developing single and multiple flechette cartridges. The Navy became sufficiently interested in the concept to provide him with some development funding from the Office of Naval Research, resulting in a 12 gauge shotgun shell firing 32 flechettes. The Army later added funding as well, and AAI was invited to SALVO. In SALVO testing they were found to be able to penetrate one side of a standard steel helmet at 500 yards --excellent given their light weight-- but the dispersion of the darts was so great as to make them not very useful.

Further development continued by adapting a Winchester Model 70 rifle with new XM110 5.6x53mm rounds firing a single dart. The result was a weapon with somewhat less accuracy than the 7.62mm NATO rounds, but with equal penetration and a trajectory so flat it could be fired with no sights out to 400 yards. Better yet the rounds were very light, and had almost no recoil in comparison to even the .22 caliber weapons under development. This meant they could be fired at extremely high rates of fire, from a very lightweight weapon.

Since the Army was by this time only interested in fully-automatic weapons, Barr suggested that they build a multi-barrelled prototype in order to quickly test the concept. The resulting "burst simulators" were tested in 1961, and the general conclusion was that the light weight of the flechette meant that it could be fired at extremely high rates of fire, the baseline being 2300 rpm, from a weapon of only 3.5 pounds, fully loaded with 60 rounds. Needless to say, the Army became terribly interested.

Meanwhile the Army's Operations Research Office, ORO, had been working on Project NIBLICK, follow-on to SALVO to develop a modern grenade launcher. Interested in the original shotgun-type shells, they recommended development of a dedicated flechette-firing weapon combined with a grenade launcher, the SPIW. The final requirements resulted in an over-under weapon, firing flechettes from one barrel, and grenades from the other. It was to weigh under 10 pounds fully loaded with three grenades and 60 flechettes.

Four companies responded to the contract tender, AAI of course, Springfield Armory, Winchester Arms and Harrington & Richardson. AAI continued with the original 5.6x53mm XM110 rounds, while Springfield and Winchester used a new 5.6x44mm XM144 cartridge. The H&R design loaded the dart from the XM144 into their own cartridge design.

The H&R design was the most advanced. It mounted the dart between three plastic sabots in a triangular plastic cartridge. When fired, the sabots were discarded early in small "sub-barrels" while the dart continued down the main barrel. Although the rounds were lightweight the weapon itself was not, at 24 pounds loaded, and the weapon was quickly eliminated from the contest.

Winchester's design used a "soft recoil" stock which absorbed the recoil of an individual round in a spring. The idea was to allow three rounds to be fired before the spring was completely compressed, meaning that there was no recoil at all until the end of the burst. This was intended to dramatically increase the accuracy of burst fire, but the system never truly worked right, and was later dropped. The grenade launcher portion of the design proved much more interesting, however, and work continued on that portion.

The Springfield entry was most interesting for its layout. It used two 30-round magazines back-to-back in a bullpup layout, taking rounds from the front magazine first. However their massive magazine-fed grenade lancher pushed the weight to 14 pounds, and it seemed unlikely this could be reduced by much.

Oddly, AAI's design was the least technically advanced. The rifle portion was somewhat heavy, but fired at 2400 rpm. Their grenade launcher was a simple single-shot weapon; their semi-automatic version was not ready in time for testing.

The conclusion of the testing was that none of the weapons was ready for development into a combat system. The AAI rifle portion and the Winchester grenade launcher were both interesting for general development however. More worrying was the results of general testing of the flechette concept. While the weapons delivered on their promise of extremely high rates of fire and excellent penetration, the rounds themselves were extremely expensive to produce, and the darts could be easily deflected in flight even by heavy rain. Finally the rounds gave off extremely loud reports and had a huge muzzle flash, making the guns easily visible in low-light.

A second round of testing followed, with the Springfield model adopting the Winchester grenade launcher with a disposable magazine and a new side-by-side layout for the flechette magazines. AAI's design was equipped with their semi-automatic launcher, which was now complete, and a new plastic buttstock/sighting system. Neither updated version proved very reliable and both were over the 10 pound limit. In 1966 SPIW was put into "maintenance mode" and the M16 adopted.

AAI continued development at a low level, and eventually managed to dramatically improve the reliability of their XM19. However this revealed another problem, that heat buildup in the chamber was great enough to result in "cook off". Changes in the Army command structure and the adoption of the M16 made interest in the SPIW fade, and eventually the project was allowed to die. Ironically AAI's original "simple" grenade launcher turned out to be a major success, when it was selected as the M203 in 1968 and became a common weapon under the M16.

But the concept simply refused to die. In 1969 the Army started the Future Rifle Program, and invited AAI to enter against General Electric|General Electric's version of the older Springfield design (Springfield had closed in 1967). Additional entries with multiple flechettes or bullets ("micro-caliber") were also entered, mirroring the original SALVO tests of the 1950s. However the program came under attack by Congress as a waste of money, and was forcibly scaled back. Testing finally began in 1974, and the AAI design never managed to fire more than 6 bursts before jaming.

It was revivied again during the semi-automatic shotgun-like Close-Assault Weapon System (CAWS) project in the early-80s. A number of designs were entered and offered fairly good reliability, but the entire concept of a large weapon for use out to 100 yards was questioned and the project later dropped ... and again during the Advanced Combat Rifle (ACR) trials in the mid-90s. Several designs were entered, from the simple Colt ACR to the more interesting flechette designs. Although the basic problem of a single-dart flechette round was finally solved by this point in time, none of the weapons entered offered the 100% improvement over the M16 that the Army tests required.

Today the SPIW is often referred to as the "deadliest weapon that never was". Given the terrible reliability problems, huge flash and high noise, it's not clear who it would be deadly to however.

Since the demise of the SPIW, there has been another attempt to revolutionize the assault rifle by way of a small projectile and a very high rate of fire, namely the HK G11. That project has not resulted in a production rifle either.

Gatling gun illustrated

in an 1885 encyclopedia

WikiPedia Entries

- volley gun

- mitrailleuse

- Category:Early machine guns

- Category:Weapons named after people

- Category:Rotary cannons

- Category:Multi-barrel machine guns

- fr:Gatling

- ja:ガトリング砲

- pl:Karabin Gatlinga

- zh:加特林机枪

External Links

- A .22LR Gatling Gun manufactured today (this is half scale operable model of a British Navy Gatling, almost twice the caliber of Reason)

- Reason.com